The settled mud from the clarifier with 6.8 to 7.0 pH and 22 to 24 Bx contains the muddy juice temperature above 80 OC. General Operational Parameters for vacuum filters: The retention time for each activity may be easily allocated for efficient operation. Now the surface area is distributed for different activities.

Segments having following distribution criteria for flow flowing activites table clearly indicate that by in design. Surface of drum is equally distributed in 24 nos. Typical Analysis of Filter Drum Working : Some sources recommend that filtrate pipes be of corrosion-resistant material, and that a generous head drop beĪrranged between the filtrate receivers and the filtrate pumps. However, vacuum Leaks in the filtrate pump seals and tanks have to be avoided.

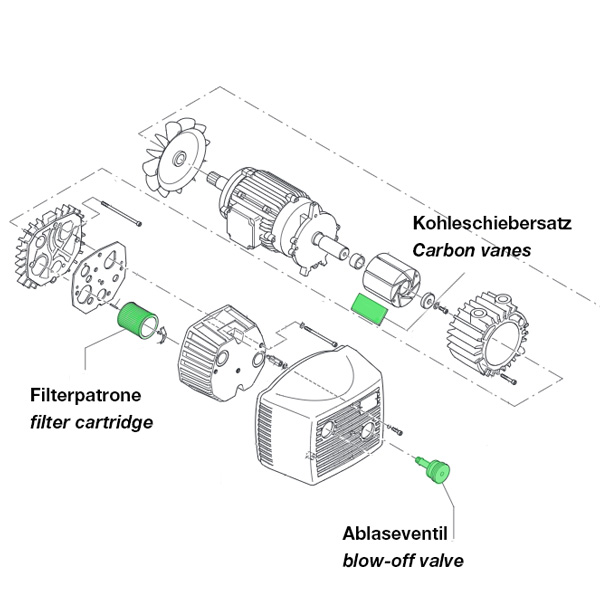

It is horizontal cylinder with corrugated surface. The filter drum rotates around horizontal axis is always partially submerged in the mud trough. In order to avoid allowing the muds in the filter tank to settle out, they are kept in movement by an agitator oscillating to and fro, pivoted on the axis of the filter, and driven by a separate small motor. The mud and bagacillo mixture is continuously feed to mud trough from the mud mixer. The mixture of mud and bagacillo is continuously feed to the mud trough of filter. In mixer fitted with sttirrer, bagacillo from mill baggase carrier is fed continuously to the mixer. The mud to filters flows by gravity from the clarifier to mixer or by pump. Vacuum pump of adequate capacity & One barometric condenser.Two number of filtrate receivers (High vacuum and low vacuum receivers).In this article discussed about vacuum filter description, its operational parameters and also explained optimization of filter cake pol (sugar loss from vacuum filter). They are well suited to applications where both dewatering and washing are required and appear to be the best of the available equipment for the treatment of cane sugar muds. 1.4 General Causes of mud trouble in Juice ClarifierĪbstract: Rotary drum vacuum filters have been widely used in sugar and a variety of other industries for.

1.3.4 Speed of the drum: 3 to 5 min per revolution.1.3.3 Wash water temperature maintained 60 to 650C.1.3.1 Vacuum ( Low and High vacuum levels).1.3 Criteria for Efficient Running or Optimization filter cake Pol.1.2 General Operational Parameters for vacuum filters:.1.1 Accessories of Rotary Vacuum Filter:.1 Vacuum Filter Operation in sugar industry | Optimization of Sugar Loss from Filter Cake.

0 kommentar(er)

0 kommentar(er)